LEMMA has strong experience in space industry. Our software NICEFLOW® is the most trustworthy developed CFD software in this area, as high order numerics and intelligent mesh allow us to precisely capture complex physics in microgravity context, coupled with FSI and sloshing problems in satellite moving tank. Please have a look at the following examples to discover a few (non confidential) studies realized in this area.

What cannot be shown here for confidentiality reasons are all the cases where LEMMA provided expertise for supervision tool development and complex control/command systems. This expertise is now transferred to other markets (follow this link to see an example in food industry).

Sloshing in tank under microgravity with surface tension

Fluid reorientation in double cassini tank under microgravity.

Cryogenic flow under micro gravity with phase change

This study was realized with success by LEMMA team and is a good example showing how NICEFLOW® is able to modelize multiphase flow with heat transfer and phase change (evaporation) under microgravity, to auto-pressurize a tank. This example implies complex thermodynamics modelisation of fluids.

Cryogenic flow in tank under microgravity.

Sloshing with heat transfer under microgravity

In this case, we consider the sloshing in a spherical tank under microgravity, taking into account fluid thermodynamics properties. Note that anisotropic adaptive mesh (see Intelligent mesh page) allows us to drastically reduce the number of mesh nodes (by 30) compared to a classical approach where all the fluid domain should have been meshed within a fine mesh to capture all the physics and free surface accurately.

Sloshing in a spherical tank under microgravity with fluid thermodynamics properties.

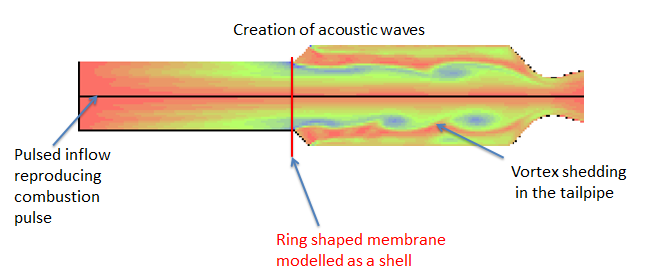

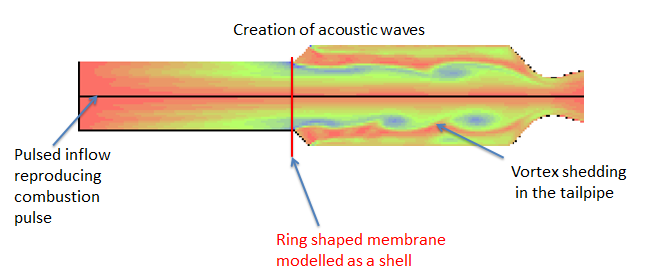

Aeroelastic coupling of a thermal protection membrane in a booster, SNPE

Space booster schematic.

Space booster FSI simulation.

Space booster membrane enhanced displacement.